NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: Time/TIG and Time advance/Tig Handle attachement for M700

Our Bolt handle fitting process for the M700 restores the Primary Extraction feature after the action has been blueprinted. Careful TIG (Tungsten Inert Gas) welding aids in joint reliability by creating a stronger union at the shear point between the bolt handle and bolt body. The process we use is a combination of welding and soldering. First, we TIG weld the joint along the shear points. The mating parts are then silver soldered to bolster the adhesion for additional strength. The combination delivers a very reliable means of permanently attaching the bolt handle to the bolt body.

When working with blueprinted receivers it is very common for the Primary Extraction function of the receiver to require additional work. Traditional "timing" involves positioning the handle so that it engages more of the receiver's cam surface. While this does work, we have to take extra measures by adding material to the bolt handle's cam surface.

This involves additional welding to "advance the timing" of the OEM handle. We are literally restoring what should have already been there to start. RR prefix serial number Remington actions are the most lethargic in this area. The cam angle is incorrect and the timing is grossly retarded in relation to the bolt's rotation. Careful welding and machine work advances the cam position and restores the timing back to where it should be.

Bolt handle removal and sterilization of bolt body and "strap" feature of bolt handle, all traces of OEM soldering/brazing operation removed:

Handle surfaces prepped for welding:

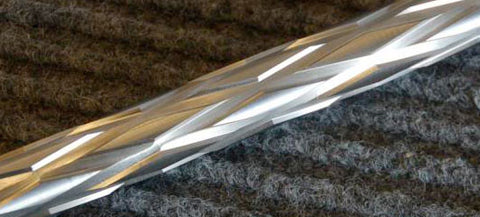

Primary Extraction cam surface welding:

Fitting and finish work of "strap" radius after welding:

Cam Surface advancement machining:

Welding and soldering:

Cleanup and final finish:

When completed, this operation advances the bolt timing so that primary extraction begins sooner in the rotation cycle while increasing the rearward travel of the bolt body.

What this boils down to is a very powerful rearward tug on the fired cartridge as you lift the bolt handle, thus improving the extraction qualities of the M700 action.

Notes:

CURRENT LEAD TIME: 2-4 Months (As of: 12.01.24)

TIG welding and soldering involve intense heat and the use of flux. Flux is a chemical used to etch and clean surfaces in preparation for soldering. These processes create discoloration and scale that cannot be avoided. Because of this, the bolt and handle will require cleaning. This is best done with abrasive blast media (bead blasting). The consequence here is that it opens the grain structure of the steel and makes it vulnerable to rust. We are happy to polish the surfaces for an additional fee. Most elect to have the bolt coated in some fashion, ie, Cerakote or parkerizing.

Please make a note of these limitations before selecting this service.

If you own an M700 with an RR prefix in the serial number, we strongly recommend this service when having the action accurized. These actions have the latest handle revision from Remington, and the PE function is almost non-existent.

You MUST send us your action for this service. Other shops do offer handle attachment services without the receiver. LRI does not. Our experience is that the only reliable means of timing an action correctly is to have the actual receiver in hand.

We Also Recommend